Best Practices for Storing Pet Food to Maintain Freshness

Proper Packaging and Handling for Optimal Preservation

Proper Materials Selection

Choosing the right packaging materials is crucial for product protection and presentation. Lightweight yet durable materials like corrugated cardboard or specialized cushioning are often ideal for fragile items, minimizing the risk of damage during transit. Consider the weight and size of the product, as well as the distance it needs to travel, when selecting the appropriate materials. Proper material selection not only safeguards the product but also reduces the risk of environmental contamination from improper packaging.

For instance, using biodegradable and recyclable materials aligns with sustainable practices, demonstrating a company's commitment to environmental responsibility. This approach enhances a positive brand image and fosters consumer trust.

Secure Closure and Sealing

A secure closure and sealing method is essential to prevent product damage and tampering. Ensuring a robust closure is vital, especially for items that are prone to leakage or breakage. Employing high-quality adhesives, tapes, or other sealing mechanisms will prevent the product from shifting or falling out during transit. Carefully consider the product's characteristics and the potential challenges it might face during shipment when selecting the appropriate sealing method.

Protective Cushioning

Providing adequate cushioning is paramount for products that are susceptible to damage. Appropriate cushioning can drastically reduce the potential for breakage or damage, particularly for items that are delicate and prone to impacts. Utilizing specialized cushioning materials like air pillows, bubble wrap, or foam peanuts can effectively protect the product throughout the transportation process. The right amount of cushioning is key to achieving optimal protection.

Consider the shape and size of the product when determining the appropriate cushioning materials and placement. This will ensure that the product is completely enveloped in a protective layer.

Labeling and Identification

Clear and informative labeling is critical for efficient handling and tracking. Detailed product information, including the item's name, quantity, and any specific handling instructions, should be clearly displayed on the packaging. This information is essential for accurate inventory management and smooth logistics operations. Proper labeling also helps prevent mishaps and ensures that the product is handled correctly.

Barcodes and other identification tags can further streamline the process, facilitating automated tracking and inventory management systems.

Handling Procedures

Implementing proper handling procedures is vital for minimizing the risk of damage. Employees should be trained on the correct techniques for lifting, stacking, and moving products to avoid unnecessary stress or strain. The procedures should include specific guidelines for handling fragile items, ensuring that they are treated with the utmost care. Following these procedures is crucial for maintaining the integrity of the product.

Storage and Preservation

Adequate storage and preservation conditions are essential for maintaining product quality. Proper storage conditions, such as temperature and humidity control, are vital for preventing spoilage or deterioration. This is especially important for perishable goods and items that are susceptible to environmental factors. Implementing proper storage procedures not only extends the shelf life of the product but also maintains its quality and value.

Storage areas should be well-organized and adequately ventilated to prevent product deterioration.

Documentation and Record Keeping

Maintaining comprehensive documentation is crucial for accountability and traceability. Detailed records of packaging, handling, and storage procedures should be kept to ensure compliance with regulations and to facilitate problem-solving in case of any issues. This documentation serves as a valuable resource for identifying potential areas for improvement in the packaging and handling processes. Comprehensive records also facilitate efficient audits and ensure regulatory compliance.

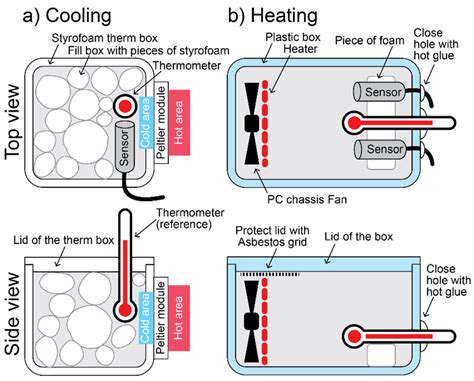

Controlling Temperature and Humidity

Maintaining Optimal Temperature

Maintaining a stable and comfortable temperature is crucial for various applications, from industrial processes to residential settings. Precise temperature control ensures consistent product quality and prevents costly equipment damage. Temperature fluctuations can lead to significant operational issues, impacting efficiency and overall performance. Understanding the factors that influence temperature, such as ambient conditions and internal heat generation, is essential for effective control strategies. This involves implementing strategies that minimize variations and maintain a targeted temperature range.

Different industries have varying temperature requirements. For example, food processing facilities need precise temperature control to ensure food safety and quality, while semiconductor manufacturing demands extremely stable temperatures to prevent defects in the production process. Proper temperature control is a critical aspect of maintaining optimal performance and minimizing risks.

Humidity Control Strategies

Controlling humidity levels is equally important in many applications. High humidity can lead to corrosion, mold growth, and reduced equipment lifespan, while low humidity can cause static electricity and damage to sensitive components. Understanding the specific humidity requirements of the environment or product is essential for effective control. Humidity control is frequently integrated with temperature control systems to optimize the overall environment. This allows for a more stable and predictable operating environment, which is crucial for many industrial processes.

Implementing effective humidity control systems often involves using dehumidifiers or humidifiers, depending on the needs of the application. These systems help maintain a specific humidity range, ensuring optimal conditions for various processes and preventing potential damage. Proper humidity control is paramount in preventing damage to sensitive equipment and maintaining optimal performance.

Impact of Temperature Fluctuations

Temperature fluctuations can have a significant impact on various processes and systems. In industrial settings, inconsistent temperatures can lead to production inefficiencies, product defects, and safety hazards. Rapid temperature changes can also damage sensitive equipment, leading to costly repairs or replacements. Understanding the potential effects of temperature variations is crucial for developing effective control strategies.

Importance of Monitoring and Feedback

Regular monitoring and feedback mechanisms are essential for effective temperature and humidity control. Real-time monitoring allows for quick identification of deviations from the desired parameters, enabling prompt adjustments to maintain optimal conditions. This proactive approach helps prevent potential problems and ensures consistent performance.

Automated systems with sensors and feedback loops are commonly used for precise temperature and humidity control. This allows for continuous monitoring and adjustment to maintain the desired environment. Automated systems significantly reduce human error and improve efficiency.

Integration with Other Systems

Temperature and humidity control systems are often integrated with other systems in a facility or process. This integration allows for a more comprehensive approach to managing the overall environment. For example, integrating with HVAC systems allows for coordinated control of temperature and humidity in buildings. This coordinated approach can improve energy efficiency and overall comfort levels.

Integration with other systems can also improve the efficiency of production processes by providing a stable and predictable environment for manufacturing or other operations. This seamless integration of controls is essential for optimized performance and sustainability.

Environmental Considerations

Environmental factors play a crucial role in determining the appropriate temperature and humidity control strategies. Different industries and applications have different environmental requirements, demanding specific control parameters. Understanding the environmental conditions and their impact on the processes is key to effective control. Factors such as geographic location, climate, and seasonal variations must be considered when implementing control systems.

Environmental considerations also extend to sustainability and energy efficiency. Choosing energy-efficient equipment and optimizing control strategies can significantly reduce environmental impact. This is crucial in today's world of growing environmental awareness.