The Environmental Impact of Pet Food Production

Kibble's Nutritional Shortcomings

While kibble offers convenience, many commercial kibble formulas fail to meet dogs' complete nutritional requirements. Heavy processing of kibble ingredients often reduces nutrient absorption and biological availability. This processing can create deficiencies in crucial vitamins, minerals, and amino acids that support canine health. Some kibble varieties contain excessive carbohydrates that may lead to obesity and related health complications.

Manufacturers frequently incorporate fillers and by-products that lack the nutritional value of whole, quality ingredients. These additives sometimes cause digestive disturbances and gastric dilation in susceptible dogs. The absence of fresh foods combined with synthetic preservatives and flavor enhancers may weaken immune function over extended periods.

The Impact on Digestive Health

The dry, dense texture of kibble presents digestion challenges for many dogs. Low moisture content contributes to constipation and other gastrointestinal issues, potentially leading to chronic discomfort. Canines with sensitive digestive systems often struggle to adapt to exclusive kibble diets.

Certain kibble components negatively affect digestive processes. Many dogs develop flatulence, abdominal distension, and loose stools from difficult-to-digest ingredients. These reactions can diminish appetite and overall vitality, creating secondary health concerns.

Manufacturing Processes and Potential Additives

Kibble production involves extreme heat and pressure that degrades nutritional quality. These harsh conditions diminish nutrient bioavailability, sometimes creating deficiencies despite theoretical nutritional completeness. Pet owners should consider these potential health implications.

Many kibble products contain synthetic preservatives, flavorings, and coloring agents. While these additives improve palatability and appearance, they may adversely affect canine health. Some animals exhibit allergic reactions or other sensitivity responses to these chemical compounds, warranting careful consideration of long-term effects.

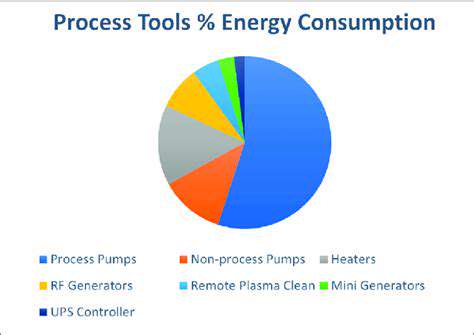

Manufacturing Processes and Energy Consumption

Material Selection and Processing

Material choices profoundly influence product characteristics and manufacturing efficiency. Engineers must evaluate strength, durability, and cost factors since different materials respond uniquely to processing techniques. Material decisions directly affect energy requirements throughout production cycles. Opting for materials with lower processing energy demands can substantially reduce environmental impact.

Production methods significantly influence energy consumption patterns. Traditional casting typically demands more energy than additive manufacturing techniques. Comprehending energy dynamics across manufacturing approaches is essential for sustainable production.

Energy Consumption in Different Stages

Energy use extends beyond primary manufacturing to encompass the entire supply chain. Extraction, transportation, processing, and distribution each contribute to cumulative energy footprints. Detailed analysis of energy expenditure at each phase enables targeted conservation strategies.

Examining energy requirements for specific manufacturing operations like forming, assembling, and finishing helps identify optimization opportunities. This scrutiny may reveal pathways for adopting renewable energy solutions.

Sustainable Manufacturing Practices

Implementing eco-conscious manufacturing methods is imperative for reducing industrial environmental impact. This involves adopting energy-efficient technologies, waste reduction strategies, and recycled material utilization. These practices yield environmental benefits while generating long-term cost savings. The transition often involves upgrading to more efficient equipment and processes.

Energy conservation in manufacturing transcends environmental concerns - it represents sound economic strategy. Sustainable operations can lower utility expenses, reduce waste management costs, and enhance market competitiveness.

Renewable Energy Integration

Incorporating renewable energy sources represents a crucial step toward sustainable manufacturing. Solar, wind, and hydroelectric power can diminish fossil fuel dependence and lower production carbon emissions. This transition is vital for establishing low-carbon manufacturing infrastructure.

On-site renewable energy generation through solar arrays or wind turbines offers energy independence and financial benefits. This approach also increases operational resilience against energy price volatility and supply disruptions.

Waste Management and Packaging Pollution

Waste Management Strategies

Comprehensive waste management systems are essential for environmental protection. Effective recycling programs, composting initiatives, and consumption reduction form the foundation of sustainable waste handling. These methods divert waste from landfills, conserve resources, and minimize ecological damage. Proper waste sorting and collection systems ensure appropriate material processing.

Public education campaigns significantly improve participation in waste reduction efforts. Raising awareness about proper disposal methods, material classifications, and recycling benefits encourages environmentally responsible behavior.

Packaging Material Selection

Packaging decisions critically impact sustainability outcomes. Selecting recyclable and biodegradable materials over conventional plastics substantially reduces environmental burden. Innovative packaging solutions that optimize material efficiency are transforming supply chain sustainability.

Evaluating packaging materials requires considering sourcing, production, and disposal factors. Designing packaging that uses minimal material without compromising product protection represents a key sustainability challenge.

Sustainable Packaging Innovations

Emerging packaging technologies are reducing environmental impacts. Plant-derived and compostable materials are replacing traditional petroleum-based plastics. These developments create packaging that decomposes naturally, easing landfill pressure and supporting circular economies.

The packaging industry continues evolving with new designs and manufacturing approaches. Lightweight packaging solutions are reducing shipping costs and material consumption, consequently lowering carbon emissions. These advancements demonstrate growing environmental commitment across industries.

Environmental Impact Assessment

Thorough environmental evaluations are essential for sustainable waste and packaging practices. Lifecycle analyses examine production energy use, transportation emissions, and waste generation. Understanding complete environmental impacts informs better material selection and waste management decisions.

Circular Economy Principles

Circular economy concepts are revolutionizing waste management and packaging. This approach emphasizes material reuse, remanufacturing, and recycling to create closed-loop systems. By maximizing material utility, we reduce dependence on virgin resources and build sustainable systems. Designing products for longevity and recyclability represents a fundamental shift toward environmental responsibility.

The Impact on Water Resources

Water Consumption in Pet Food Production

Pet food manufacturing requires substantial water resources at every stage. Water is essential for cleaning agricultural ingredients, processing animal proteins, and maintaining equipment hygiene. Large-scale facilities particularly strain local water supplies, potentially worsening scarcity in vulnerable regions. Water treatment and purification further increase the industry's environmental footprint, with wastewater management presenting additional challenges.

Water Pollution from Pet Food Production

Pet food processing generates wastewater containing various contaminants, including chemical residues, agricultural runoff components, and pharmaceutical traces. These pollutants can trigger algal blooms, oxygen depletion, and aquatic ecosystem disruption. Inadequate wastewater treatment can cause severe water quality degradation, underscoring the need for rigorous environmental regulations.

Water Scarcity in Feed Production Regions

Pet food ingredients often originate from irrigated agricultural regions facing water stress. Growing global demand intensifies competition between pet food production and human water needs, potentially creating shortages that impact local communities and food security.

Impact on Groundwater Resources

Excessive groundwater extraction for pet food ingredient irrigation can deplete aquifers, cause land subsidence, and reduce water tables. Sustainable water management practices are crucial in arid regions where groundwater represents a vital resource. Water-efficient irrigation and alternative water sources can help mitigate these impacts.

Regional Variations in Water Impact

Water resource impacts vary significantly by location due to climate, regulations, and production methods. Water-stressed regions bear disproportionate burdens from pet food production. Understanding these geographic differences enables targeted conservation strategies and international cooperation for sustainable solutions.

Consumer Choices and Industry Responsibility

Consumer Awareness and Sustainable Practices

Modern consumers increasingly consider environmental impacts when selecting pet food. This awareness drives demand for sustainable products, prompting manufacturers to adopt eco-friendly practices. Informed consumers examine ingredient sourcing, production methods, and corporate sustainability commitments when making purchasing decisions.

Sustainable Ingredient Sourcing

Responsible agricultural practices minimize pet food's environmental footprint. Consumers should favor brands using local ingredients, sustainable protein sources, and ethical farming methods. These choices reduce transportation emissions and support environmentally conscious producers.

Packaging and Waste Management

Eco-conscious packaging represents a critical sustainability factor. Consumers can support this by choosing products with minimal, recyclable packaging and properly disposing of pet food containers. Manufacturers must continue innovating to reduce packaging waste.

Manufacturing Processes and Energy Efficiency

Energy-efficient production methods significantly lower pet food's environmental impact. Consumers should support companies investing in sustainable technologies and transparent about their manufacturing processes. This transparency enables informed decisions about corporate environmental responsibility.

Transportation and Distribution

Reducing transportation distances and optimizing logistics decreases the carbon footprint of pet food distribution. Consumers can minimize impact by choosing locally produced options and supporting brands with sustainable supply chains.

Consumer Responsibility and Education

Informed consumer choices drive industry-wide sustainability improvements. By prioritizing eco-friendly products and sharing knowledge, pet owners can collectively influence manufacturers toward greater environmental responsibility. This collaborative approach accelerates the transition to sustainable pet food systems.